SMALL SAIL AND MOTOR SHIPS - METAL AND POLYESTER HULLS Corrosion is your n°1 ennemy!

Galvatest  detects electrolysis before it is too late...

detects electrolysis before it is too late...

* They follow a metallic path to the sea resulting in corrosion and/or paint blistering.

Galvatest, leader in small ships corrosion control!

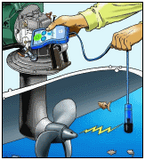

Galvatest Sensors

Galvatest Controller

Galvatest Kits

from aboard or ashore.

Wood or polyester hulls: mind the sail-drives!

Did you know? Unlike metal hulls, boats made of wood or polyester (GRP...) are particularly at risk: as their hulls do not carry electricity, metal propulsion devices are necessarily over-solicited.They represent the only way to the sea for unwanted leakage currents from aboard or ashore!

Steel or aluminium metal hulls: a well-known evidence!

They are primarily concerned by electrolysis and the regular control of their corrosion potential. Such control is conducted in "real time" on all big ships and is an integral part of formal ABYC (American Yacht and Boat Council) recommendations for all recreational boats in aluminium. Be very careful with your hanging anodes: if they are made of magnesium at sea, they will be likely to destroy your immersed paint work...

Electric propulsion: a true challenge!

The gradual implementation of electric propulsion will pose new challenges for builders and yachtsmen. A formidable enemy of submerged metal equipments, electrical energy, now available on board in large quantities, involves best practices in terms of wiring, earthing management and integrity controls...

The White Paper about cathodic protection...

Regularly supplemented and updated, the 2024 edition includes some attacks commonly encountered on oxido-protected metals: stainless steel, aluminium and bronze.

Galvatest round the world with Energy Observer...

Follow on www.energy-observer.org

Regular control of metal hulls and immersed equipments corrosion potential is a recommended practice of international standards and major boat and equipment manufacturers. All our electrodes sensors are individually tested. Patented technology. Galvatest is a member of Normandie Maritime. They trust us:

Information

FREE Boaters :

the comics "How goes your boat?"

To understand quickly and without painful headache, download our explanatory comic strip. You will learn, with just a few pictures, how to use Galvatest to assess instantly cathodic protection level given by anodes, and if harmful stray currents are eating your boat.

Prices...

Prices...